Cold chisels may seem like simple tools, but their versatility and usefulness extend beyond their basic appearance. From metalworking to masonry, woodworking to sculpting, these sturdy tools have found their way into various trades and crafts, offering precise cutting and shaping capabilities.

In this article, you’ll explore the practical applications of cold chisels across different industries and highlight their importance in various projects.

Metalworking: Crafting Precision with Cold Chisels

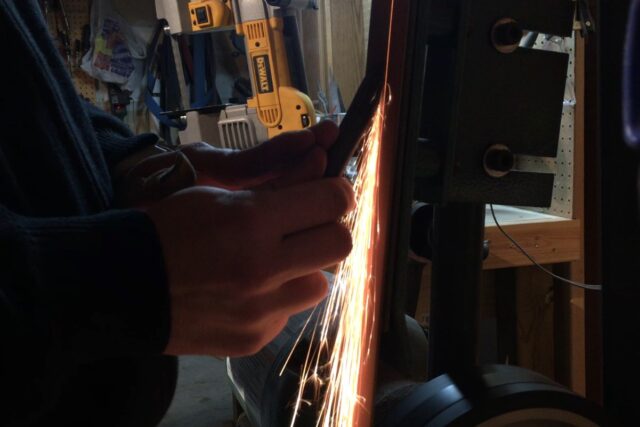

Cold chisels are indispensable tools for shaping and cutting metal in metalworking. Whether shaping sheet metal, cutting through thick steel bars, or carving intricate designs into metal surfaces, cold chisels offer the precision and control required for the job.

Metalworkers rely on these tools to create precise cuts and clean edges, ensuring the quality and integrity of their work.

Masonry Work: Carving Through Stone and Concrete

Cold chisels are crucial in masonry in shaping and sculpting stone and concrete. Masons use these tools to carve intricate details, create precise joints, and shape rough surfaces into smooth finishes.

Whether cutting bricks to size, chiselling away excess mortar, or sculpting decorative elements, cold chisels provide the necessary precision and power to tackle even the toughest masonry projects.

Woodworking: Crafting Fine Details with Cold Chisels

Woodworkers also use cold chisels to shape wooden pieces and carve intricate designs. Whether carving out mortises and tenons, shaping wood joints, or detailing fine woodworking projects, cold chisels offer the control and precision needed for precise cuts and smooth finishes.

Woodworkers choose their tools carefully, opting for reliable suppliers such as Mektronics to ensure the quality and durability of their equipment.

Sculpting and Artistry: Expressing Creativity with Cold Chisels

Cold chisels are essential for shaping and sculpting various sculpture and artistic craftsmanship materials.

Artists use these tools to carve intricate details, refine shapes, and bring their creative visions to life. Whether sculpting stone, wood, or metal, cold chisels give artists the precision and control they need to achieve their desired results.

Automotive and Construction: Precision Workmanship with Cold Chisels

Cold chisels are invaluable tools for cutting, shaping, and removing metal components in the automotive repair and construction industries.

Mechanics use them to cut through rusted bolts, remove stubborn parts, and shape metal surfaces to fit precise specifications.

Similarly, construction workers rely on cold chisels for tasks such as cutting through rebar, shaping concrete, and removing excess materials, ensuring their projects’ structural integrity and quality.

Safety Considerations: Ensuring Protection While Using Cold Chisels

While cold chisels are invaluable tools in various industries, it’s essential to prioritise safety when using them.

Safety precautions, such as wearing protective eyewear and gloves, are crucial to prevent injuries from flying debris or accidental slips. Additionally, ensuring a stable work surface and maintaining control over the chisel can help prevent accidents and maintain precision.

By prioritising safety alongside reliability and precision, craftsmen can maximise the effectiveness of cold chisels in their projects while minimising the risk of accidents or injuries.

Maintenance Tips: Extending the Lifespan of Cold Chisels

Regular maintenance is essential to ensure the performance and longevity of cold chisels. After each use, cleaning the chisel thoroughly is important to remove any debris or residue that could impair its effectiveness.

Additionally, inspecting the chisel for signs of wear or damage and addressing any issues can help prevent premature wear and ensure consistent performance.

Proper storage in a dry environment away from moisture and humidity can also help prevent rust and corrosion, extending the tool’s lifespan.

By following these maintenance tips, craftsmen can maximise the lifespan and efficiency of their cold chisels, ultimately saving time and money in the long run.

Conclusion

Cold chisels may appear simple, but their practical applications are diverse and essential across various industries and crafts.

From metalworking to masonry, woodworking to sculpture, and automotive repair to construction, these versatile tools offer precision, control, and reliability in tackling various tasks.

Choosing reliable suppliers ensures that craftsmen and professionals have access to high-quality tools that meet their needs and uphold the standards of excellence in their work.

So whether you’re shaping metal, carving stone, or crafting wood, a cold chisel is a tool you’ll want in your arsenal.